Common questions about the current chip shortage with up-to-date answers from Summit 360

By now, you’re probably already aware that manufacturers across several industries are feeling the pinch of a global computer chip shortage. Production delays and product availabilities are a temporary new normal for auto manufacturers, consumer electronics companies and even energy companies.

It is likely that the shortage will eventually affect cloud and enterprise data centers, too. That means timelines for acquiring new networking, server and storage equipment could be delayed.

As we navigate the uncertainty of the shortage together with our clients, below are some frequently asked questions and our most up-to-date answers.

How did the chip shortage happen?

It all boils down to two key issues — production shutdowns and supply chain delays.

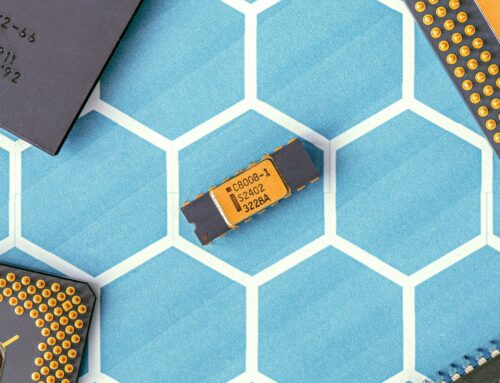

To start, there are only a small number of computer chip manufacturers globally. These factories had to close at the beginning of the pandemic, which created a production backlog: lots of chip orders piling up with too few production lines to get the job done.

Today, these manufacturers are still chipping away at their chip order backlog.

On top of the backlog, the demand for technology that uses chips increased exponentially during the pandemic as people geared up with new tech during the lockdown. This means the already enormous backlog just got bigger and bigger.

But that’s not all…

The complex supply chain that produces chip technology is made of many fragile links. That means there are many companies working together that depend on one another to produce a finished product. The chip manufacturers’ suppliers are having the same production line issues as everyone else: lots of orders and a shrunken capacity to meet those orders.

Related Reading: The Computer Chip Shortage and How Summit 360 Can Help

How is the chip shortage affecting businesses?

Chip shortages directly impact the cost of electronics and the time it takes to fulfill orders. Any organization with an IT department can expect two things:

- With chips harder to come by, they’ll be more expensive when they are available. In particular, the cost of hardware like servers and networking equipment could be affected soon. This will be a fundamental supply/demand challenge that organizations will have to work to overcome.

- You may not be able to rely on orders getting fulfilled as quickly and as thoroughly as they have in the past. For example, According to a New York Times article this year, HP could not meet the demand for computers ordered by school systems because of the chip shortage.

Planning much further ahead will be critical, as will finding new and different ways to meet your equipment needs.

Why is a chip shortage so hard to fix?

The main reason why the chip shortage is so difficult to overcome is the time it takes to increase capacity — it can take years to grow or optimize manufacturing processes for greater output.

Increasing capacity involves a) adding equipment to existing facilities – adding yet another supply chain dependency – or b) building additional, brand new plants.

Some major manufacturers are already starting to make large investments in their production capacity. Intel, for example, has announced it will spend $20 billion to build two new chip plants in Arizona, but these will not go into operation until 2024.

When will the chip shortage be over?

It’s impossible to say for certain, but Gartner predicts this shortage will last through Q2 of 2022.

Others suggest the impacts of this shortage could last much longer — two-plus years.

Either way, the computer chip shortage isn’t going away any time soon. In the long term, supply fixes will depend on maturing investments in manufacturing capacity that could take longer than two years to fully integrate into the supply chain.

What if my company cannot wait for new hardware?

Refurbished, excess and open market hardware does not have the same supply chain restraints as the new equipment market. Shopping in these secondary markets is a great way to get the tech you need quickly.

Summit 360 will access these alternative channels for you, delivering hardware that is often ready to ship immediately, oftentimes with existing OEM support or Summit 360’s own Peak Select Lifetime Warranty.

Another consideration is simply extending the life of your current infrastructure with enhanced support and maintenance. Summit 360 is an independent hardware maintenance company that can support his option, too. Learn more about Summit Global Care enterprise technical support.

Have Summit 360’s lead times been affected by the shortage?

A variety of brands and configurations (including current generation) are available, but we are seeing things change on an almost daily basis.

Current customers and inquiries can SIGN UP for our email newsletter to stay informed on the latest updates on lead times.

What can I do today to prepare for supply chain issues in the near future?

If you’re in need of a reliable networking solution amid the global chip shortage, the secondary market experts at Summit 360 are standing by with real, reliable solutions.

Contact us today or download our free guide to purchasing like-new, refurbished IT equipment.